CO162

AUTOMATIC CONTOURING MACHINE FOR SHOE BOTTOMS

MULTITOOL

PROFILE ACQUISITION DEVICE

SIMULTANEOUS EXECUTION OF THE PAIR

TECHNICAL FEATURES TO SUPPORT OF INDUSTRY 4.0

- Smart and touchscreen HMI

- CNC control system

- Remote maintenance and remote diagnosis

- Remote maintenance and remote diagnosis

- Automated integration with the system logistics factory

- Machine status monitoring sensors

- Compliance with the latest safety standards

CO162 is an automatic contouring machine for shoe bottoms. Born from the development of the previous CO981, it has been reconfigured in a perspective of greater versatility and productive efficiency, while keeping a high quality processing standard.

CO162 can sand-paper, brush or mill the different types of shoe bottoms with excellent results and productivity up to 300 pairs per hour.

The acquisition system allows detecting any type of profile with variable inclines throughout the contour.

The completely renewed software allows programming complex processes with great easiness and efficiency.

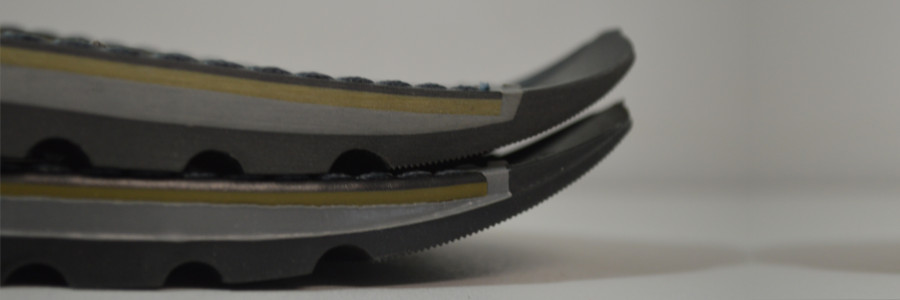

The significant integrations made on the equipment allow using 2 different tools on the same profile, making of CO162 an extremely versatile machine for any type of shoe bottoms.

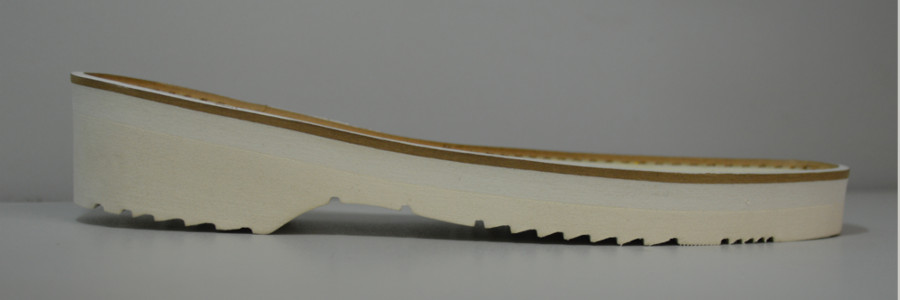

TYPES OF PROCESSED BOTTOMS

- Soles in single block TR/PVC

- Soles in PU

- Soles in EVA

- Assembled leather soles

- Single blocks in cork, wood, etc.

- Units in micro, rubber, etc.

- Rubber soles

PROCESS TYPES

- Sand-paper

- Creping

- Brushing

- Milling

To see the video of machine at work

For further information and to get the product technical data